Evaluate Color Tolerance on the Display.

CC Display turns your display into a soft-proofing station and renders colors on the screen very accurately. The Monitor has to be qualified and a measurement Instrument is required, but the procedure is fast and easy to perform. It is possible to have colors that are out of the gamut of the display (making it impossible to render accurately but ChromaChecker will alert you if your color(s) are beyond the display's capabilities of rendering inaccurately. Having a calibrated and profiled display (soft proofing) reduces prints and saves time and money. We have prepared a methodology on how to accurately display your key colors using ChromaChecker Snowflake (useful for defining color tolerances) or other PDFs.

Steps

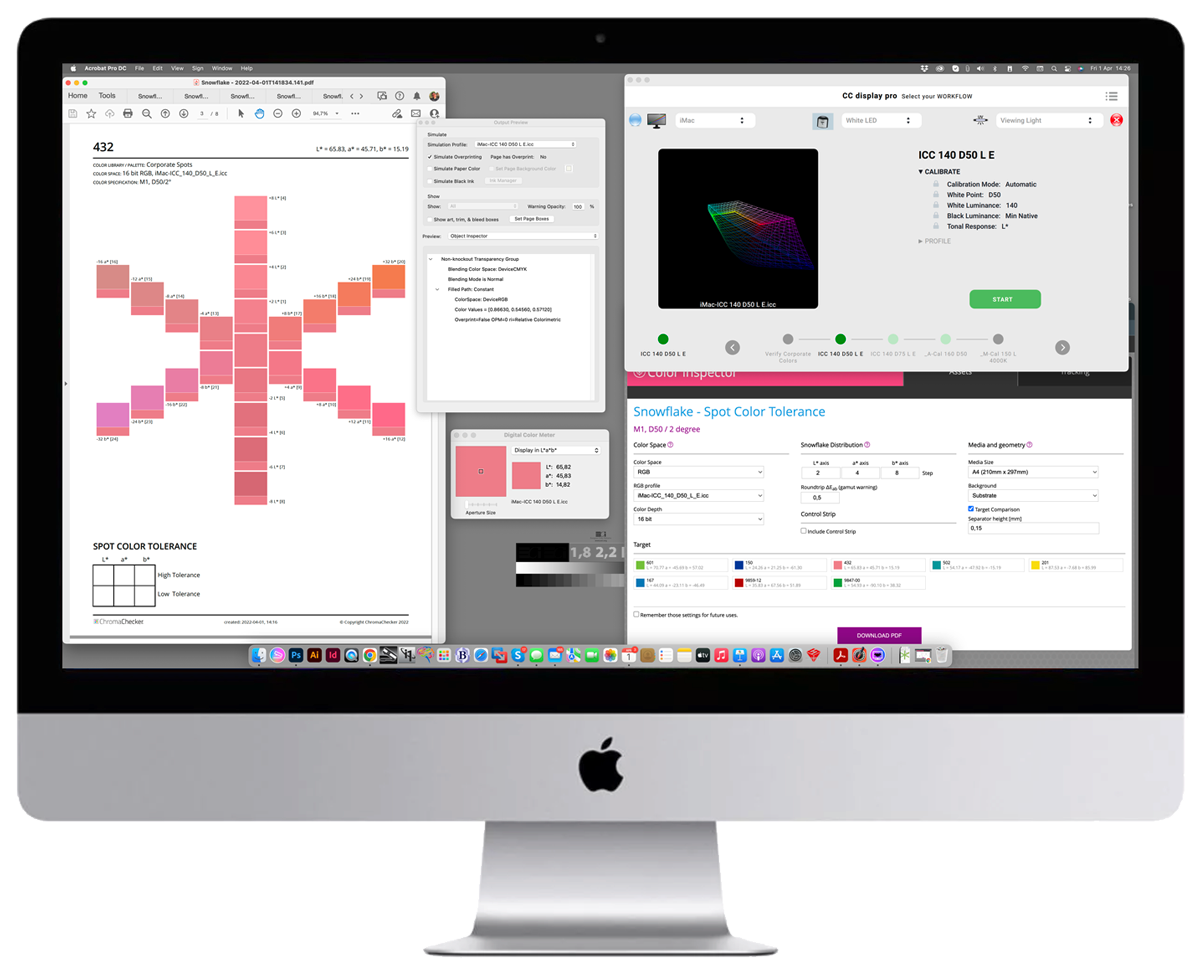

- Launch CC Display - Calibrate and Profile your Display to be sure that the monitor is in the proper state. If you recently created a new profile activate it instead.

- In the Color Space (Grid or Snowflake) section select RGB, next find your last created ICC Display Profile, then create a PDF

- Display PDF using Adobe Acrobat Pro DC — from "Print Production" open the "Output Preview" window; select your Display ICC Profile as "Simulation Profile"; in "Preview" select Object Inspector

- Optionally, on Mac launch Digital Color Meter (system application), which can read color coordinates from the screen.

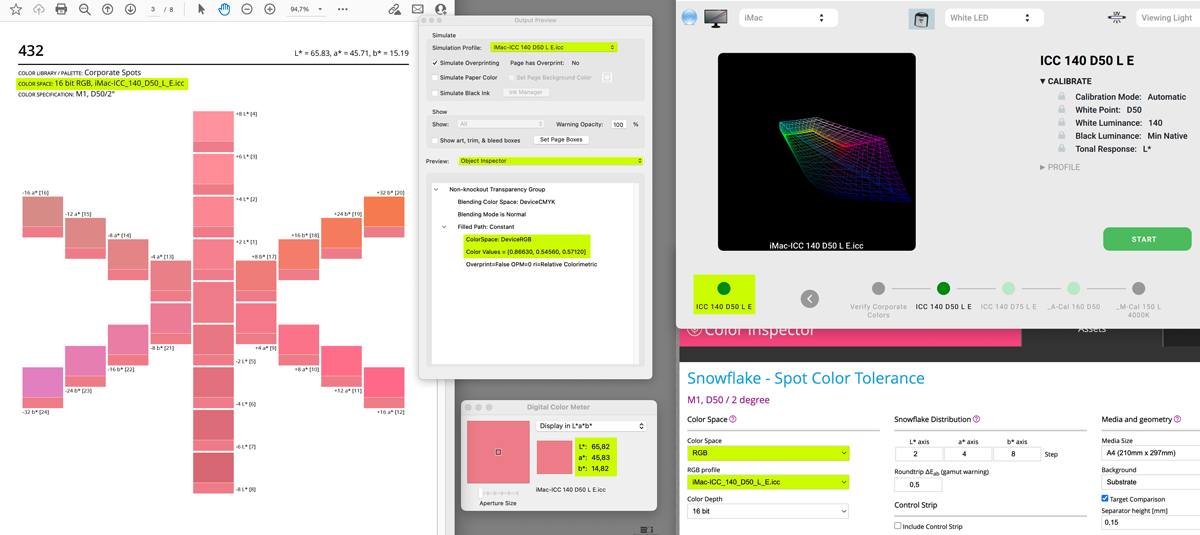

Sample 1

Please check all critical parameters before evaluation (highlighted on the screenshot below)

| L* | a* | b* | |

| Target | 65.83 | 45.71 | 15.19 |

| Digital Color Meter | 65.82 | 45.83 | 14.82 |

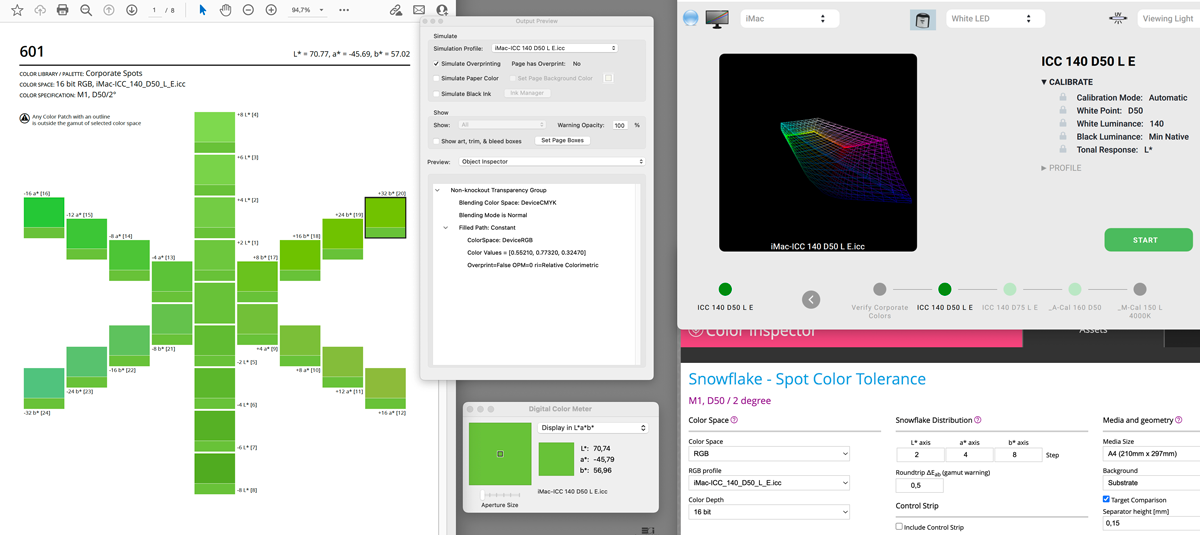

Sample 2

| L* | a* | b* | |

| Target | 70.77 | -45.69 | 57.02 |

| Digital Color Meter | 70.74 | -45,79 | 56,96 |

Please note that one patch is outlined - this one exceeds the roundtrip error set to 0.5∆E telling you it is out of gamut on this display

Important note:

- Neither ICC Profiles nor Color Management Engines are ever 100% accurate today. All profiles have roundtrip error so perfect results cannot be expected!

- No instrument on the market is 100% accurate, all instruments measure differently, even same make and model.

- No monitor is perfectly uniform and stable

Unarguable:

Calibrated and profiled monitors speed up the process and reduce the number of iterations. Also, tolerances can be assigned for soft-proofing purposes. Additionally, the display errors are generally much smaller than most print processes since printers have significantly higher variations and deviations.

CC Display provides a high level of accuracy and consistency to any remote workgroup allowing precise color communication no matter where the participants are located. Learn how to start here.

Read more about how to evaluate Color Library for soft-proofing purposes here. Also, see how easy evaluate all samples from the color library (free demonstration version).

Comparison to physical objects

CC Display can evaluate Lighting Conditions and offers methodology and tools that help adjust lighting conditions in the Light Booth that match the Display. Some Viewing Light Booths can be even remote-controlled by the CC Display software.

It is important to understand that a soft-proofing station requires complete control over the environment including 1) Ambient light, 2) Viewing Booth Light, and neutral walls and 3) Computer display all matched to one another.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.