Print Industry »

Print Industry »

Working with Spot colors »

Options for setting exacting Tolerances »

Display first - it saves time and consumables!

April 5, 2022

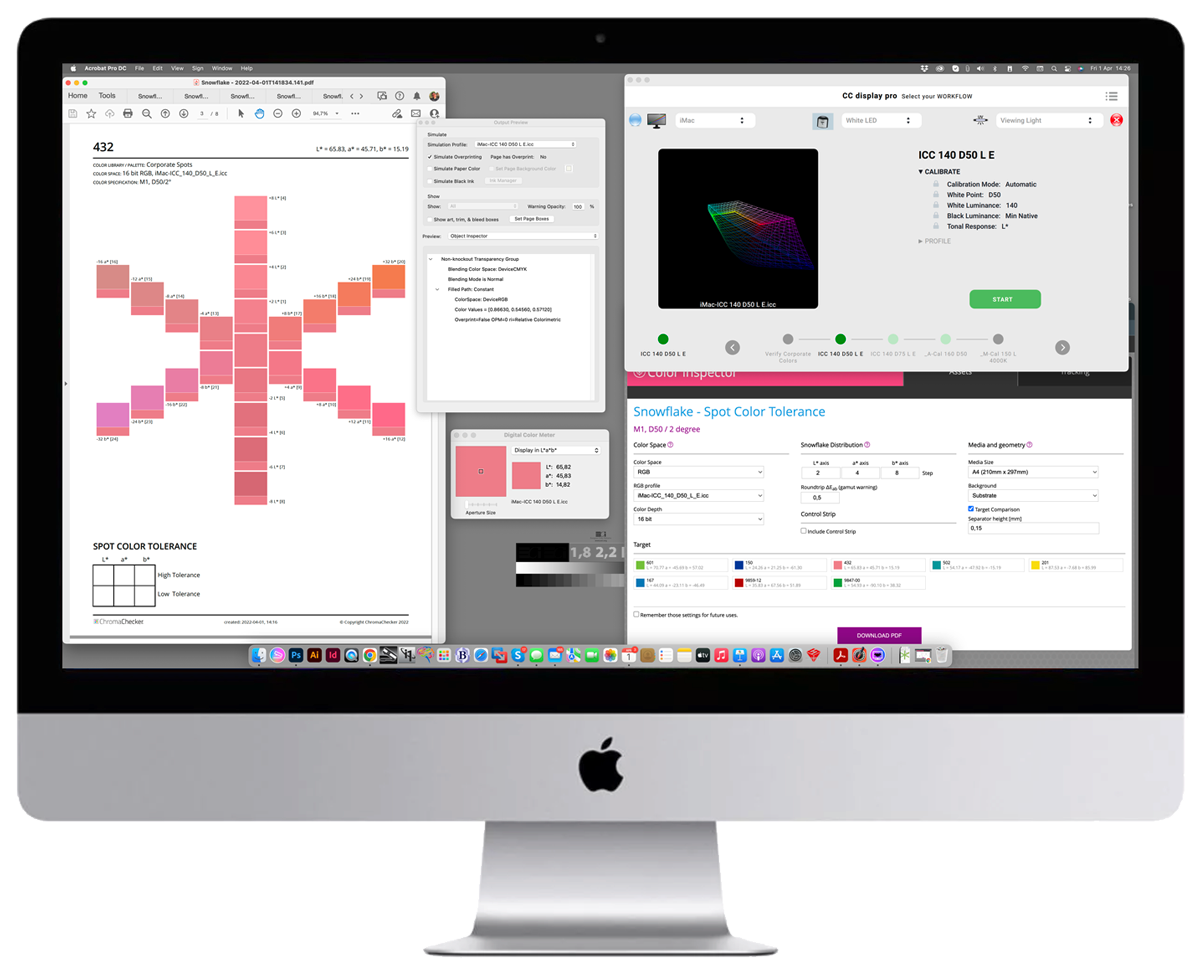

Display first - it saves time and consumables!

CC Display turns your display into a soft-proofing station and renders colors on the screen very accurately. The display has to be qualified and a measurement instrument is required, but the procedure is fast and easy to perform. It is possible to have colors that are out of the gamut of the display (making it impossible to render accurately but ChromaChecker will alert you if your color(s) are beyond the display's capabilities of rendering accurately. Having a calibrated and profiled display (soft proofing) reduces prints and saves time and money. We have prepared a methodology on how to accurately display your key colors using Snowflakes.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.